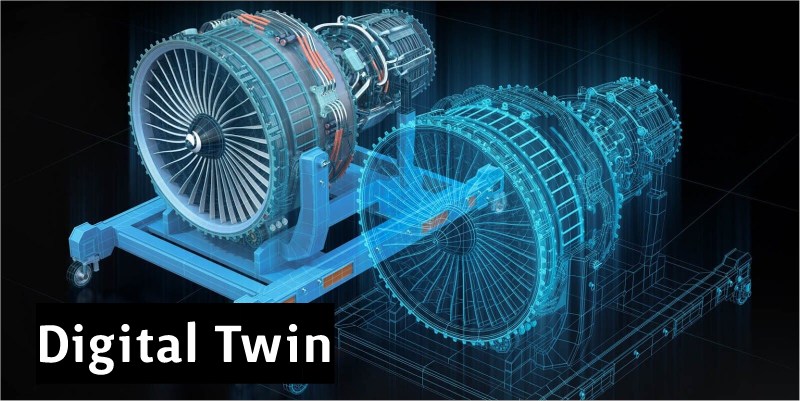

The use of digital twin technology is becoming more and more widespread among businesses of all sizes and in many sectors. The strength of digital twins, which derives from linkages between real-world and virtual worlds, has significantly altered global enterprises. This digital depiction can continuously monitor the actions and results of its physical counterpart.

Businesses may model and optimize their operations, forecast problems, and increase the efficiency gains of their processes with the help of digital twins. Similar to how NCS, a provider of digital solutions, can assist other companies in going digital with the aid of digital twin technologies.

What is Digital Twin?

A “digital twin” is a replica (copy) of a physical system, a digital good, or a service that is continuously updated. Many businesses can use digital twins to enhance operations and precisely identify risks. They use digital data and analytics to deliver performance insights.

The aerospace and defence industries have utilized digital twin technology for many years. To create digital twins for space programming, Michael Grieves coined the term “digital twin” in 2002. Grieves popularised the concept when he introduced digital twin technology. At that time, digital twins became a mainstay of projects aimed at implementing digital transformation in various sectors, including manufacturing, retail, and healthcare.

How Digital Twin Works

Digital computing is at the core of digital twin technology. Given that they are digital copies of existing systems, this is how digital twins received their moniker. Using digital modeling tools like Computer-Aided Design, Augmented Reality (AR), and Virtual Reality (VR) technology produces digital twins (CAD).

Digital twins connect the digital and physical worlds using digital sensors and interfaces. The biological entity’s digital sensors provide data to the digital twin, which then processes the data using an analytics engine to produce information on the system. Making informed decisions that optimize operations and procedures is possible using this data.

The Phases of Digital Twin Technology

The development of digital twin technology happens in four stages.

In the initial stage, digital models are created using software for digital modelling, such as CAD. The digital model represents the physical system’s behaviour and design.

In the second phase of deployment, digital sensors are coupled with the digital model using digital twins. This uses digital interfaces like smart sensors and the Internet of Things (IoT). The digital sensors record real-time data from the physical system.

Digital twin analytics, which uses digital twins as a platform for digital analytics, is the third phase. This digital analytics engine processes the data from digital sensors and provides insights that can be used to enhance operations and procedures.

The optimization of digital twins is the fourth stage of technology. At this point, digital analytics are used to enhance the design, functionality, and upkeep of the digital model. Through digital optimization, it may be possible to decrease downtime, increase resource usage and production, and lower operating costs.

The Principle Behind Digital Twin Technology

Knowing the underlying premise of digital twin technology is crucial to comprehending the value they provide to businesses. To collect digital data and do digital analytics, digital twins are digital copies of physical systems. This digital data can predict problems, optimize operations, and raise the system’s effectiveness in the real world.

The Principle Behind Digital Twin Technology

Examine a previously designed and constructed building as an illustration. Imagine if the roof, vents, engineering, and plumbing systems of that structure are all digital twins. The digital twin will get real-time digital data about the building, including its temperature and humidity levels, via the establishment’s sensors.

Using digital analytics, digital twins can then forecast when a particular system needs to be repaired or how well ventilation is working. Similarly, sensors on the building’s structural engineering systems will give digital twins information on where the structure is at risk of failing structurally or where the building is ageing. The owner of the building can then take precautions to avoid this structural failure.

On a larger scale, an entire ecosystem can be built using several digital twins. Digital twins of various industrial processes in a plant. It is possible, for instance, to connect to digital twins of related systems, such as those for machinery, marketing, advertising, customer service, and security. This enables companies to optimise their digital operations at an enterprise scale using digital twins as a platform.

Future environmental and weather monitoring systems could incorporate digital twins on a far wider scale. The data from these digital twins can be used to forecast weather disasters.

Types of Digital Twins

Physical assets, digital sensors, models, analytics, and optimization are the foundation of a digital twin. Digital twins of a variety of shapes and sizes can be created using the data collected from digital sensors.

The most prevalent kind of digital twins are representations of complete factories or digital copies of machines. These “digital twins” offer a digital replica of the machinery or factories while collecting digital data and performing digital analytics to reveal performance insights.

Digital twins also allow for the replication of digital users, customers, and marketplaces.

Digital twins of goods or services, for example, can be used to monitor online performance, user behaviour, user engagement, pricing, advertising campaigns, and promotions.

Improved user experiences and digital operations are possible with the help of this data.

An individual’s digital twin can record digital data and digital statistics on their online activities, online preferences, online purchasing behaviour, online lifestyle, online health, and online behaviour. This digital data can offer insights into the potential for digital engagement, digital marketing initiatives, digital health interventions, and digital lifestyle modifications. A digital copy of a person is another kind of digital twin.

Conclusion

To further enhance their operations, other industries will eventually adopt digital twins. Digital twins’ potential uses will develop over time as technology advances and matures. Digital twins will continue to offer digital insights and analytics to enhance digital operations across various industries with the correct implementation strategy and digital resources.

The potential for digital transformation is enormous, and there are no limits to the possibilities of digital twins. Digital twins have the potential to revolutionize how businesses operate by making them more effective, adaptable, and efficient.

Also read: the Casino Industry

Also read: Hormonal Acne Symptoms